Long Island has been a hub for innovative surfboard designs for over 60 years, all inspired by our unique and constantly changing shoreline.

Founders of the region’s surfboard makers, Charlie Bunger, John Hannon, Bob Hawkins, Eddie “Fast Eddie” McCabe, and the dozens of innovative shapers they contracted crafted designs that adapt specifically to the wave breaks on Gilgo, Long Beach, and Ditch Plains Montauk.

However, like the shifting sands of the shore, the terrain, designs, and trends evolve, leaving Bunger and Paul Schmidt as the premium board makers and a dwindling number of board craftsmen for the next generation to come.

Board shaping is endangered of becoming a lost art.

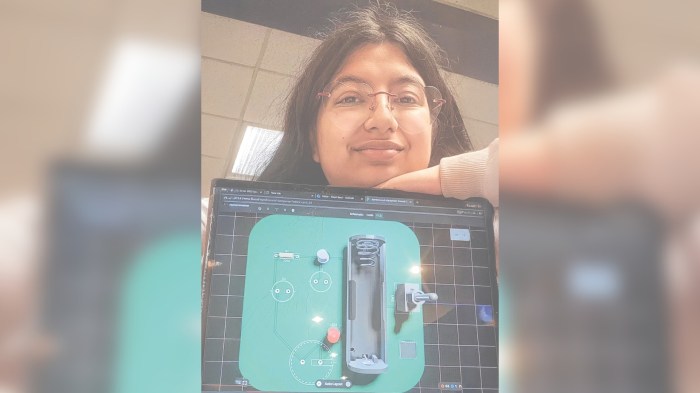

In Lonelyville, 15-year-old Calvin Hills has been obsessed with surfing since he hit his first wave at age 8. His obsession has now become a potentially lucrative business, which will secure his spot in local history as the first surfboard manufacturer on Fire Island.

“I got into surfing during the Covid lockdown of 2020 when my family moved to Lonelyville full-time. Places I surf on the Island are Democratic Point and Saltaire,” stated Hills.

Hills started the production of surfboards after researching, board shaping, and networking with the online community of board designers last summer. Under the stilts of his parent’s Lonelyville home, Hills tarped off the sides, placed drop cloths on the ground, and began operations. His new board and apparel company is named Ulu.

Ulu is a popular phrase in the Olelo Hawai’i language, defined as “to grow.” This name defines his company’s goal of doubling the production of boards each year.

“My boards are designed for Fire Island waves. The waves throughout the island are steep, requiring a more curved nose to prevent nose-diving,” Hill explained. The tail shapes range from swallow to squash tail. “The swallow tail holds the wave tighter on turns; you kind of ride along the side of the wave, as compared to the squash; you are looser on the turns.”

Production of the boards and his other products prioritizes the environmental impact. He uses epoxy foam instead of the traditional polyester foam, which releases less volatile organic compounds into the air. An additional environmentally friendly effort is his surfboard recycling. To reduce broken surfboards from going into landfills, Hills requested locals with broken boards to drop them off at his house instead of discarding them. Hills gives these boards a second life by reusing the foam to build hand boards for body surfing. But Hill’s most distinctive trademark in all his boards is the four-leaf clover locally picked and implanted in the board for good luck.

“We do not have surfboard shops out here, and how he shapes his boards all by himself is amazing,” stated surfer Toby Heslin of Lonelyville. When asked which one of Hills’s boards he prefers, Heslin answered, “I prefer Hills’s squash tail surfboard; it goes fast, straight, and looser on the turns.”